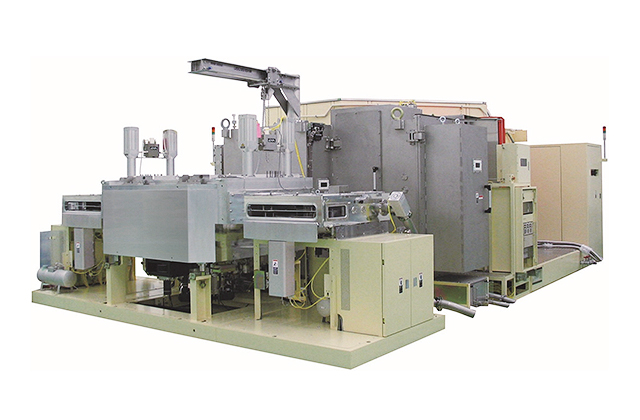

Ion implanter for FPD manufacturing

iG4

We provide ion implanters that are indispensable for the electrical characteristics control process in the manufacture of thin-film resistors for driving high-definition displays, as typified by low-temperature polysilicon thin-film transistors.

We provide ion implanters that are indispensable for the electrical characteristics control process in the manufacture of thin-film resistors for driving high-definition displays, as typified by low-temperature polysilicon thin-film transistors.

Merit

- High equipment reliability as recognized at mass production plants around the world

- A single implanter can handle a variety of dopants and a wide implantation range (channels and source/drain regions).

- High precision and high reproducibility are achieved by our proprietary high-precision ion beam measurement system and high-precision glass substrate scanning mechanism.

- Rapid switching between different dopant recipes using proprietary technology

- High-purity implantation through proprietary technology for mass separation impurity removal

- Suppression of glass substrate temperature increases during implantation by means of a dual platen mechanism

- Mitigation of glass substrate charging (electrostatic discharge damage) during implantation by means of a charge neutralization system

- High equipment reliability as recognized at mass production plants around the world

- A single implanter can handle a variety of dopants and a wide implantation range (channels and source/drain regions).

- High precision and high reproducibility are achieved by our proprietary high-precision ion beam measurement system and high-precision glass substrate scanning mechanism.

- Rapid switching between different dopant recipes using proprietary technology

- High-purity implantation through proprietary technology for mass separation impurity removal

- Suppression of glass substrate temperature increases during implantation by means of a dual platen mechanism

- Mitigation of glass substrate charging (electrostatic discharge damage) during implantation by means of a charge neutralization system

Main Specifications

Available glass substrate sizes

730 mm x 920 mm

Dopants (ion species)

B+、P+

Ion beam energy

10–80 keV

Track Record

Delivered to display panel manufacturers and laboratories in Japan, China, South Korea, and Taiwan.