About Our Ion Implantation Services ABOUT

Nissin Ion Equipment Co., Ltd. offers ion implantation services that have been developed in-house. In addition to implantation for cutting-edge silicon devices utilizing 300mm wafers, we also offer high-temperature implantation for SiC and GaN devices and hydrogen ion implantation for VCSELs. (We can also handle small-diameter wafers and small pieces.)

We also conduct implantation evaluations utilizing annealing furnaces, surface resistance measurement devices, dose monitors, and particle measurement devices.

We have prepared an environment that can be used for your device development. We invite you to make use of our ion implantation services.

We provide a clean-level environment equivalent to that of our customers’ LSI production lines.

We provide support for device development and experimentation for nano technology nodes.

Fields Served by Our Ion Implantation Services

Silicon devices

High-precision, high-purity ion implantation

SiC, GaN, and Ga₂O₃ power devices

Al⁺, Si⁺, and Mg⁺ implantation

High-temperature implantation up to 600°C possible

GaN and SiC Smart Cut wafers

Wafer stripping through high-concentration hydrogen implantation

VCSEL (Vertical cavity surface emitting LASER)

High-energy hydrogen implantation

Cutting-edge process development

We support the development of new technologies that use specific ion types, etc.

Merit MERIT

High-quality implantation services

- Customers can make use of ion implantation using our state-of-the-art ion implantation technology, which is available for most advanced implantation processes. (wafer size: 300 mm)

- High-quality ion implantation required for state-of-the-art implantation processes is available.

- Our implantation services are available in a clean environment located inside a Class 1 clean tunnel.

- We provide support for nano technology node device development and implantation experiments.

Merit of the EXCEED Series

- Beam parallelism controllable to ±0.5° or less

- Parallel beams

- Functionality for checking uniformity of expected implantation prior to implantation

- Functionality for complete elimination of energy contamination

- Load Port FOUP

The end station is connected to the clean tunnel, allowing the implantation process to occur within a Class 1 environment.

Merit of the IMPHEAT-II

- High-temperature implantation with wafer temperatures of up to 500°C

- Aluminum ion implantation

- Parallel beams

- Beam parallelism controllable to ±0.5° or less

- Functionality for checking uniformity of expected implantation prior to implantation

- Functionality for complete elimination of energy contamination

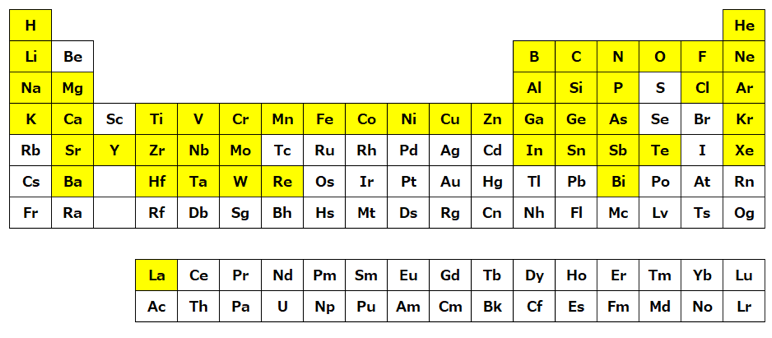

Implantable Ion Species

Our implanter for 8-inch wafer can implant a variety of ion species other than those commonly used in semiconductor production lines.

This capability is available for research and development of new devices as well as for contamination evaluations of devices.

●: Implantable Ion Species

Ion Implantation Simulations

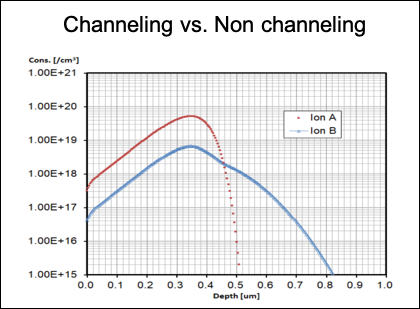

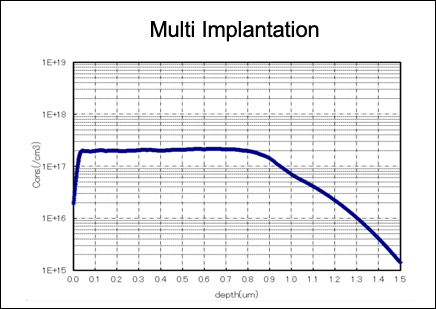

Ion implantation simulations can be performed in order to achieve the customer’s desired ion implantation distribution.

Please let us know your desired ion species, implantation depth, and distribution shape. We will use a dedicated simulation to study your request.